Design & Construction

U.S. nuclear plant structures were designed and built to survive massive earthquakes. The NRC requires that the design of U.S. nuclear energy facilities take into account the most severe natural phenomena historically reported or expected for the site and surrounding area. Additional safety margin is then added into a nuclear facility’s design to ensure they withstand much stronger earthquakes than expected. This safety margin not only ensures the survivability of the facility following a natural event that exceeds historical data, but it also ensures the reactor can safely be shut down and cooled using any number of reactor cooling options. Additional equipment, such as large shock absorbers and heavy-duty support (see seismic bracing photo above), protects critical safety systems.

View Columbia's physical barriers which limit release of fission products

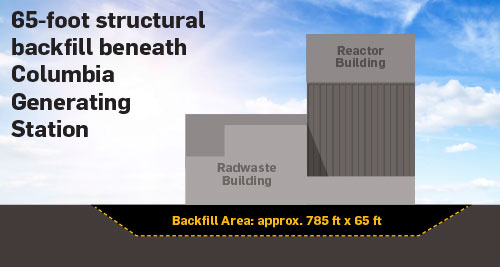

Columbia’s built-in safety margin began with preparation of the new construction site in the 1970s. The soil at the site was removed to a depth of 65 feet and replaced with structural backfill soil – soil specially engineered based on composition and gradation, and then compacted to meet optimum density requirements. Because this backfill is very dense, it is not subject to liquefaction, or the process by which water-saturated sediments transform into a liquid-like substance during an earthquake. It is liquefaction that undermines the foundations of a structure during a seismic event, and can cause serious damage.

Additionally, should an earthquake result in the loss of offsite power, Columbia has three giant diesel generators that will continue to power important plant functions, plus two, smaller, but still quite large diesel generators – one mobile and the other static. Two seismically rated buildings constructed in 2014 separately shelter the smaller generators, along with other emergency equipment such as a fire truck for use as a portable water pump, an earth mover, a front-end loader, hoses, connectors and back up parts and spares. Columbia also has large installed battery systems which can power equipment directly. All this equipment is regularly tested and stringently maintained.

Seismic Sensors ...

Traditionally, large earthquakes are preceded by increased seismic activity. Columbia has three accelerometers that record seismic motion.

These sensors are monitored from the plant’s control room, and set to begin recording when vibrations from a seismic event produce even mild ground motion accelerations of 0.01g (gravitational force). The seismic motion detectors are linked to two control room alarms:

- The “Minimum Seismic Earthquake Exceeded” alarm that is set to alarm at 0.01 g. (This is the minimum detectable value.)

- The “Operating Basis Earthquake Exceeded” alarm is set to alarm at 0.125 g.

If any of the seismic monitors detect Columbia’s minimum detectable ground motion set point of 0.01g, then Columbia control room operators initiate appropriate, procedural emergency action plans. Should the facility require shutdown, all structures, systems and components related to plant safety are designed to ensure safe shutdown while withstanding the effects of an earthquake.

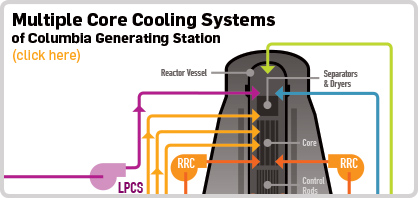

View Columbia's Core Cooling Systems

Fukushima Comparisons ...

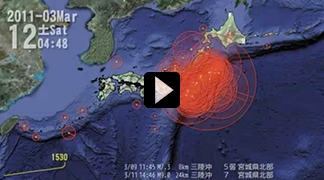

The Fukushima plants safely survived the magnitude 9.0 Tohoku earthquake of March 11, 2011, an event well beyond the seismic design requirement of those facilities. Eleven reactors at four facilities in the region were operating at the time and all shut down automatically when the quake hit. This includes the Onagawa nuclear station, which was closest to the source of the earthquake. Control rods were automatically inserted into the reactors, and emergency generators came online as designed to power electronics and coolant systems. The plants were structurally sound and safe after the earthquake. Onagawa facilities even provided temporary shelter for displaced local residents.

The video above demonstrates the seismic activity in Japan prior to, and after, March 11, 2011. The size of the circles and the sound denote the strength of individual earthquakes. (Source: EQForecaster/YouTube). Find the complete video here: http://youtu.be/NSBjEvPH2j4

But the Japan facilities were not designed to withstand the effects of the 45-foot tsunami that followed. At Fukushima Daiichi, the wave flooded battery rooms and disabled emergency diesel generators, heat exchangers and electrical switchgear. Loss of power and failing systems prevented reactor cooling, which led 25 hours later to a hydrogen explosion that blew the roof off the Unit 1 building; three days after the tsunami to a larger hydrogen explosion that demolished the top of the Unit 3 building; and four days after the tsunami to both a rupture of the pressure suppression chamber under the Unit 2 reactor, and a hydrogen explosion (backflow from Unit 3) that destroyed the top of the de-fueled Unit 4 building. Although all four reactors remained intact, radioactive release peaked on the fourth day from airborne fission products carried into the atmosphere, apparently mostly from the Unit 2 hydrogen explosion. On day eight, Japan’s Nuclear & Industrial Safety Agency reported that radiation levels had stabilized within a range that allowed workers to safely continue on-site recovery measures.

The Tohoku earthquake claimed nearly 19,000 lives, including two workers who drowned at Fukushima Daiichi. There have been no deaths or cases of radiation sickness from the nuclear accident, but more than 100,000 people had to be evacuated from their homes. As of May 2014, many evacuated area residents were still unable to fully return home due to government-mandated restrictions. Decontamination work is proceeding while radiation levels decline naturally.

Post-Fukushima Inspections ...

The NRC stated very strongly in the wake of the Fukushima disaster that all U.S. nuclear plants are safe. Nevertheless, within days of the accident, reviews of safety equipment and seismic safety procedures were under way at all U.S. nuclear energy facilities. All U.S. reactors completed safety inspections and walk-downs in March 2011 to ensure that facilities and equipment are protected in the event of extreme natural hazards.

As part of this response, Columbia engineers with structural and safety equipment expertise performed seismic inspections on more than 130 nuclear safety systems and related components and supporting structures. Although the inspections did not reveal any degraded or nonconforming conditions with regard to current seismic license requirements, minor ways were discovered to further improve safety margins. For instance, batteries for starting diesel engine-driven fire pumps were not strapped down to battery holder platforms, and the holder platforms were not bolted to the ground. The batteries were immediately strapped to the platforms, and the platforms bolted down. NRC inspectors followed with independent walk downs of the facility and inspection reviews.

Earthquake Hazard Analysis ...

The NRC also initiated an industry-wide re-evaluation of ground motion estimates compared to plant design parameters for safe reactor shutdown. The re-evaluation includes two important sets of data: the likelihood that a given site might experience various ground motions, and the range of ground motion and frequencies (whether the shaking is fast or slow) that a nuclear facility could experience in approximately 25,000 years.

Two separate modeling methods are used for the re-evaluation. The first model addresses seismic activity at the source of a seismic event and models the associated bedrock motions from the source to the nuclear facility. The second model uses the bedrock motion determined from the first model and applies it to a facility-specific site characterization model. This model uses actual soil properties collected from subsurface soil bore holes around the site. The bore holes extend from the surface down to bedrock.

The NRC completed their review of facilities east of the Rocky Mountains in May 2014, and required 21 of the 59 sites to conduct further, in-depth analyses of their earthquake risk. At that time, the commission stated that the central and eastern plants have substantial safety margin above their designs’ anticipated hazards, and are safe for continued operation while further studies are conducted.

Columbia’s new earthquake hazard estimates, using data gathered by the Pacific Northwest National Laboratory study, will be submitted to the NRC for review by mid-March 2015.

A Flexible Response Strategy...

The most important lesson from the accident in Japan is that the industry must be prepared to handle catastrophic events simultaneously at multiple reactors, regardless of the cause. In response, the industry stationed another layer of backup equipment at regional depots in Phoenix and Memphis. As of June 2014, the Phoenix regional response center is ready to deliver a full set of portable safety equipment, radiation protection equipment, electrical generators, pumps and other emergency response equipment to Columbia within 24 hours. This is equipment beyond the backup generators, portable water pump, construction equipment, hoses, connectors and other back-up safety supplies already at Columbia.

Flex equipment information - PDF Format

The industry continues to work with the NRC, an independent regulatory body which has on-site, full-time inspectors at each of America’s nuclear energy facilities, to implement some of the most stringent safety measures in the world.

Shake, Rattle and Analyze...

Earthquakes come in various shapes and sizes. These differences can have differing impacts on a nuclear plant and its components. Low-frequency earthquakes – which can shake back and forth a few times per second – can create visible motion and are more likely to cause structural damage. Higher-frequency earthquakes – which can shake back and forth 20 to 30 times per second – are less likely to cause structural damage, but might have impacts on sensitive electronic equipment.

Ensuring that sensitive electronic equipment such as switches, relays, and circuit breakers will function as designed and when needed is essential in providing the confidence that nuclear plants will safely shut down if an accident occurs.

The Electric Power Research Institute in Charlotte, N.C., launched a seismic test program in 2014 to answer this core question: Could electronic switches, relays, and related equipment known to operate properly during low-frequency seismic tremors continue to operate properly if ground movement occurred at higher frequencies than previously assumed?

The below video, released in May 2014, describes the test program that EPRI is conducting to evaluate more than 100 types of electronic equipment in use at nuclear power plants. The results will be used by nuclear operators to check for potentially vulnerable parts in their plants and decide whether replacement or compensatory actions are needed.

Seismic Testing at Electric Power Research Institute (EPRI)