At Energy Northwest’s Industrial Development Complex (IDC), the end of an era is approaching.

Located just east of Columbia Generating Station, the staff at the IDC have been steadily scrapping and demolishing most of the structures remaining from Washington Nuclear Projects 1 and 4 (WNP-1 and WNP-4). The sister nuclear stations were 70% and 30-40% complete, respectively, when they were mothballed in the early ’80s and then shuttered in conjunction with the Washington Power Supply System bond default.

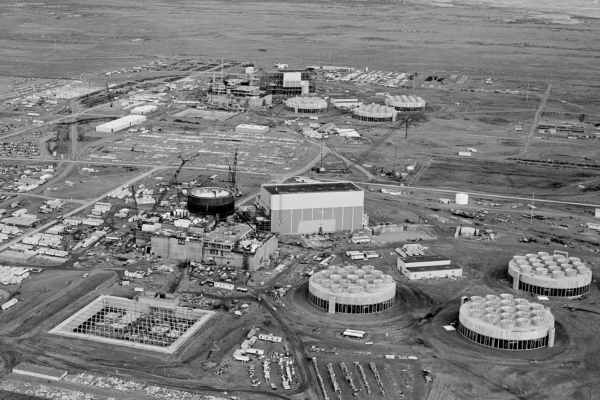

Above: Aerial photo of Sites 1 and 4 during construction in the late 1970s, early 1980s.

Today, efforts to restore the sites are nearly complete, well ahead of the required schedule and significantly under the projected budget.

Managing restoration

The restoration work is guided by what is known as the “four-party agreement” between the Bonneville Power Administration, Energy Northwest (EN), the Department of Energy and the Washington Energy Facility Site Evaluation Council (EFSEC). Signed in 2003, the agreement lays out the timeline, funding and requirements of restoring Sites 1 and 4. It calls for EN to begin restoration no later than 2026 and complete by 2029, with a projected cost of $45 million (in 2003 dollars).

Crews work on demolition near the cooling towers.

That timeline seemed a little slow for Jack Kerr, who is overseeing the restoration effort for EN.

“We convinced Bonneville back in 2016 that it would benefit them to go ahead and start restoration early,” Kerr said. “Time is money, and if we waited to get started, the cost was going to keep going up.”

BPA approved, and Kerr’s team of contractors began demolition in 2017. The agreement requires the sites to be restored to brown field, Kerr said. The only evidence that will remain of the nuclear structures are Site 1’s domed reactor building, general services building and a few other concrete structures on Site 1 and 4. The parties agreed these structures could remain due to the high cost of demolition.

Inside, the structures are mostly empty – gutted of copper, nickel, stainless steel and other shiny metals, which were sold for scrap to recoup some costs. Other equipment, such as 12 large stainless steel heat exchanger tubes, were also scrapped.

“The reactor building contained 100% of the equipment needed to run the plant,” Kerr said. “By selling the metals, we were able to recoup about $12 million for BPA.”

The reactor core containment structure at site 4 is demolished.

After scrapping ended in 2019, Kerr’s team began demolition. Crews removed the six cooling towers, spray ponds, service water pumphouses and air intake structures. Some of the concrete was used to fill in the spray pond pools, and then covered with 50,000 cubic feet of dirt.

“After the structures are removed, we have to bring in fill dirt, level it out and then we let the desert take over,” Kerr said.

And taking over it is. The region’s high winds do a good job of seeding the new soil, and in many areas it is no longer obvious where the structures formerly stood.

Funding restoration

From a regulatory standpoint, the decommissioning process is written in as part of the application to build a nuclear power plant. But beyond that, environmental stewardship is a core value for both BPA and EN.

“BPA is committed to environmental stewardship, and that includes minimizing the impact of this project and restoring it as close as we can to where it was before,” said Cherie Sonoda, supervisor of Contract Generating Resources for BPA.

The four-party agreement called for BPA to set aside the projected costs in a restoration fund. Those funds can only be used to support restoration activities. Originally projected to cost $45 million, around $20 million has been spent so far. Once the four parties certify that the restoration has been completed to the agreement’s requirements, any remaining funds will go into BPA’s general fund to offset current ratepayer costs, Sonoda said.

“Jack’s cost-containment strategies ensured we met the requirements of the four-party agreement in the most cost-effective manner,” Sonoda said. Kerr even received a Meritorious Service Award from EN’s Executive Board in recognition of the sale of scrap in the turbine and generator buildings that resulted in $2.2 million in revenue.

Site 1 (foreground) and site 4 (background) as they appear today. The cement structures will remain.

Remaining pieces

Beyond major structural removals, the restoration agreement required EN to close-up groundwater wells on the site and clean up an old landfill.

BPA funded the construction of a water treatment facility on Site 1 to support closure of the groundwater wells. Construction was completed in 2022 and the facility is in the commissioning process. Once finished, it will provide potable water to the IDC buildings, support Columbia operations and any future facilities on the site.

The water treatment facility was able to make use of the river pumphouse that was built to support Sites 1 and 4, but never used. EN’s Facilities & Commercial Engineering crew ran electricity to the structure, installed new pumps and two miles of pipeline to bring water from the Columbia River to the new treatment facility.

EN is currently working with EFSEC and the Department of Ecology to close out the landfill. Once completed to everyone’s satisfaction, the sites will be officially restored.

Future of Sites 1 and 4

With the closure of the restoration effort, EN is beginning to look to the future and how the land could be repurposed to meet the region’s growing energy needs.

EN is actively working with X-energy to pursue funding for an advanced reactor project on Site 1. Among the advantages are the existing river pumphouse and piping, transmission lines to the Ashe substation, and previous licensing and environmental permitting activities that will be useful in licensing the sites for new reactors.

“Site 1 is ideally situated to be the home of the first advanced reactor in Washington state,” said Greg Cullen, vice president for Energy Services & Development at EN.

“By meeting our commitment to the public to restore these sites, we open up the opportunity for new development. By pursuing an advanced reactor, not only do we bring new economic growth to our region but we continue to be a leader in supplying safe, carbon-free, baseload power that is available to our customers 24/7.”

This story was originally published in the May issue of Northwest Public Power Association’s Bulletin magazine.